Zengben Research and Development Center and Automated Production Line

Evolution of Hardware and Speaker Accessories Industry: The Path to Intelligent Manufacturing at Zengben

Automated Production Line

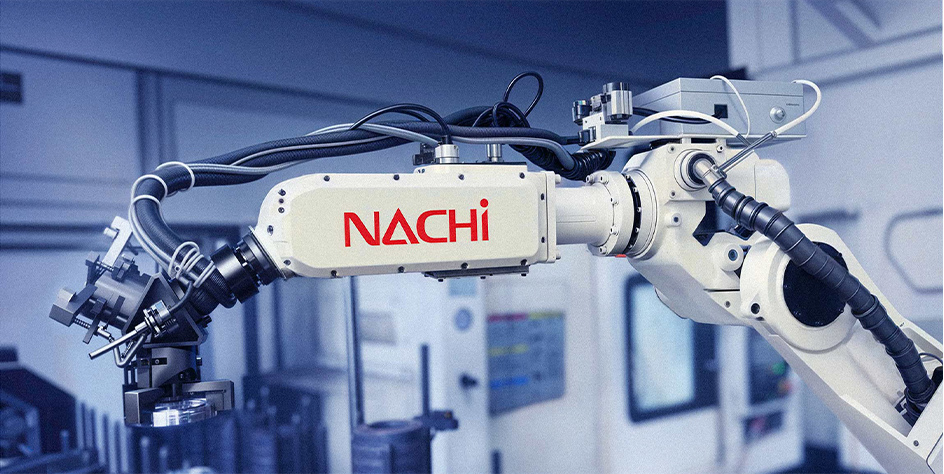

In May 2016, our company introduced an automated production line with CNC from Zhejiang Haideman Machine Tool Manufacturing Co., Ltd., valued at RMB 1.65 million. The main machine has a spindle output power of 15kw/11kw, with a maximum rotation diameter of 550mm, a maximum processing diameter of 330mm, and a maximum processing length of 280mm. It includes an 8-inch solid chuck and 8-tool turret. This equipment utilizes the SIEMENS 828D CNC system. To pursue ultimate productivity, we also introduced a series of fully automated multi-jointed robotic arms made by the globally renowned Japanese company, Nachi-Fujikoshi. These robotic arms have 6 degrees of freedom, offering high operational flexibility. They can reach a maximum speed of 210° per second in rotation, 185° per second in back-and-forth movement, and 270° per second in up-and-down movement. The powerful high-speed motion and precise control capabilities enable our robotic arms to excel in various industrial applications. These arms not only guarantee Japanese manufacturing quality, ensuring optimal results for your products but also provide uninterrupted support to our production and workflows all day long. Their outstanding performance and precise control allow us to offer exceptional capabilities in various industrial applications. Additionally, these robotic arms are designed to adapt to diverse working environments, featuring IP67 dust and splash protection, with rust-resistant screws and parts, ensuring excellent performance and longevity in various conditions. These robotic arms have not only improved our production efficiency but also enhanced the flexibility of our factory layout, allowing us to more adaptively meet diverse production demands.

Research and Development Center

Innovation in Smart Manufacturing: Leading the Global Evolution of Speaker and Hardware Accessories Industry.

In January 2019, our company reached a new milestone with the establishment of a professional Research and Development Center. The core mission of this innovative center is to delve into smart manufacturing technologies, automation technologies, as well as the research and development of various product processes and cutting-edge technologies. To ensure the continuity and stability of our R&D, we have established a robust funding mechanism for research and development and actively promoted various R&D activities. Specifically, in 2019, our R&D expenditure was 861,200 yuan, which significantly increased to 4.658 million yuan in 2020. Through continuous scientific innovation, our company has greatly improved in terms of smart manufacturing level, product craftsmanship, and labor productivity, ensuring the development and mass production of new products within 30 days. This high efficiency and quality execution have established a good reputation for us globally, making us a world-renowned supplier of speaker accessory T-iron. For a long time, our company has maintained a leading position in the industry. With advanced R&D capabilities and extensive production experience, we firmly believe that with our professionalism and dedicated pursuit, we will continue to provide our customers with the highest quality products and services to meet their needs and drive the development of the industry.